Flight Control Actuation

Whippany Actuation Systems is the technology leader in electromechanical flight control components and subsystems, supporting applications for commercial and military airplanes, rotorcraft, unmanned systems, and missiles. All of our products are designed, developed, manufactured, and certified in accordance with the strictest customer, industry, government, military, and regulatory requirements and regulations.

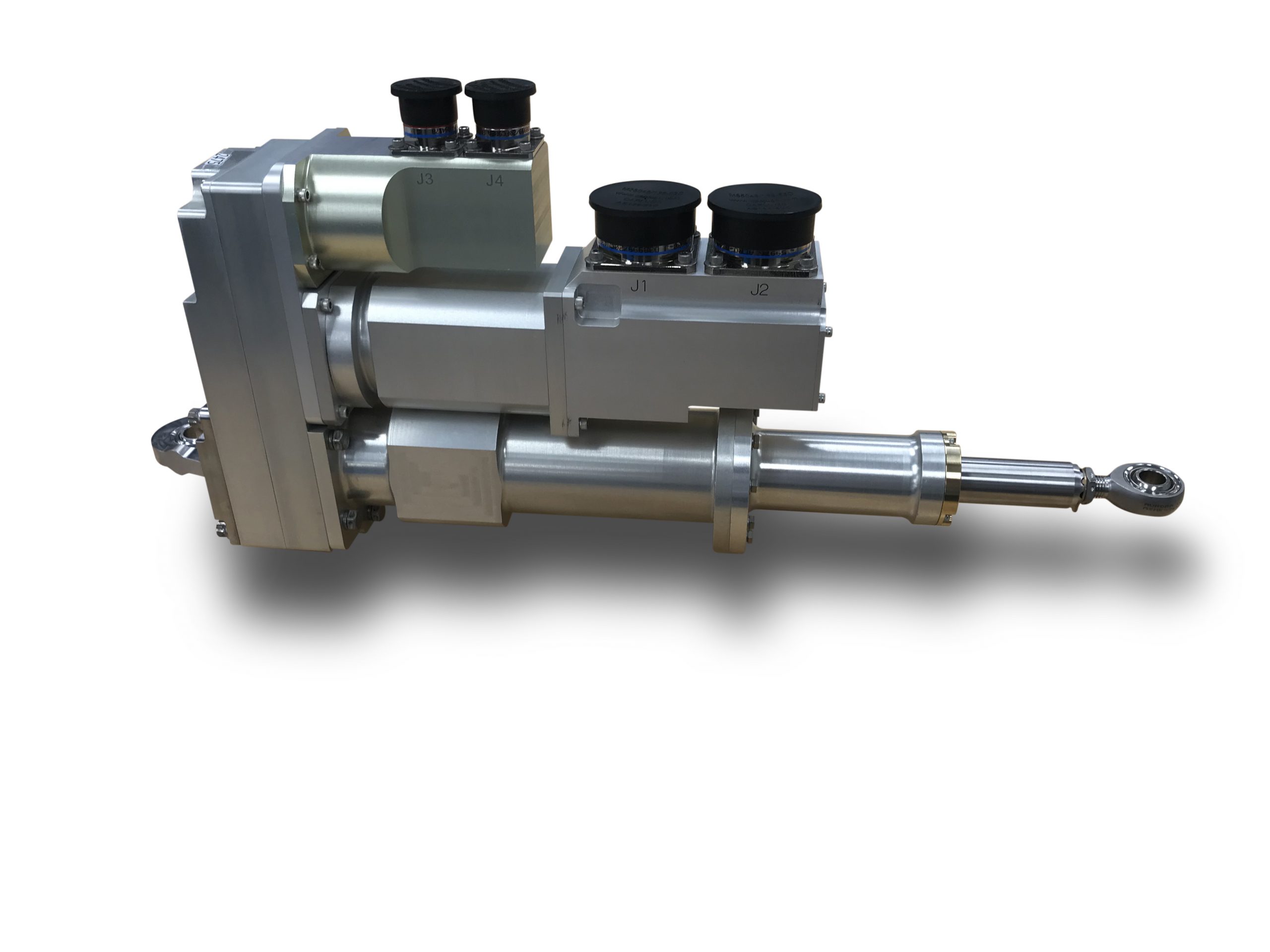

Primary Flight Control Actuation

Controlling all primary flight control surfaces, our primary electric flight controls offer lighter and more reliable alternatives to hydraulic systems.

- Aileron

- Elevator

- Rudder

- Ruddervator

- Flaps

- 28VDC, 270VDC, +/-270VDC motors

- Up to 45kW sinusoidal and trapezoidal drive systems

- High bandwidth, fully digital 3-loop control systems

- Fault tolerant, redundant control architectures

- Regenerative energy management

- Active-active and active-standby motor architectures

- Ball screw linear and geared rotary transmissions

- Transport

- Business jets

- Helicopters

- eVTOL

- UAV

- Missile

- Control Surfaces

-

- Aileron

- Elevator

- Rudder

- Ruddervator

- Flaps

- Features

-

- 28VDC, 270VDC, +/-270VDC motors

- Up to 45kW sinusoidal and trapezoidal drive systems

- High bandwidth, fully digital 3-loop control systems

- Fault tolerant, redundant control architectures

- Regenerative energy management

- Active-active and active-standby motor architectures

- Ball screw linear and geared rotary transmissions

- Applications

-

- Transport

- Business jets

- Helicopters

- eVTOL

- UAV

- Missile

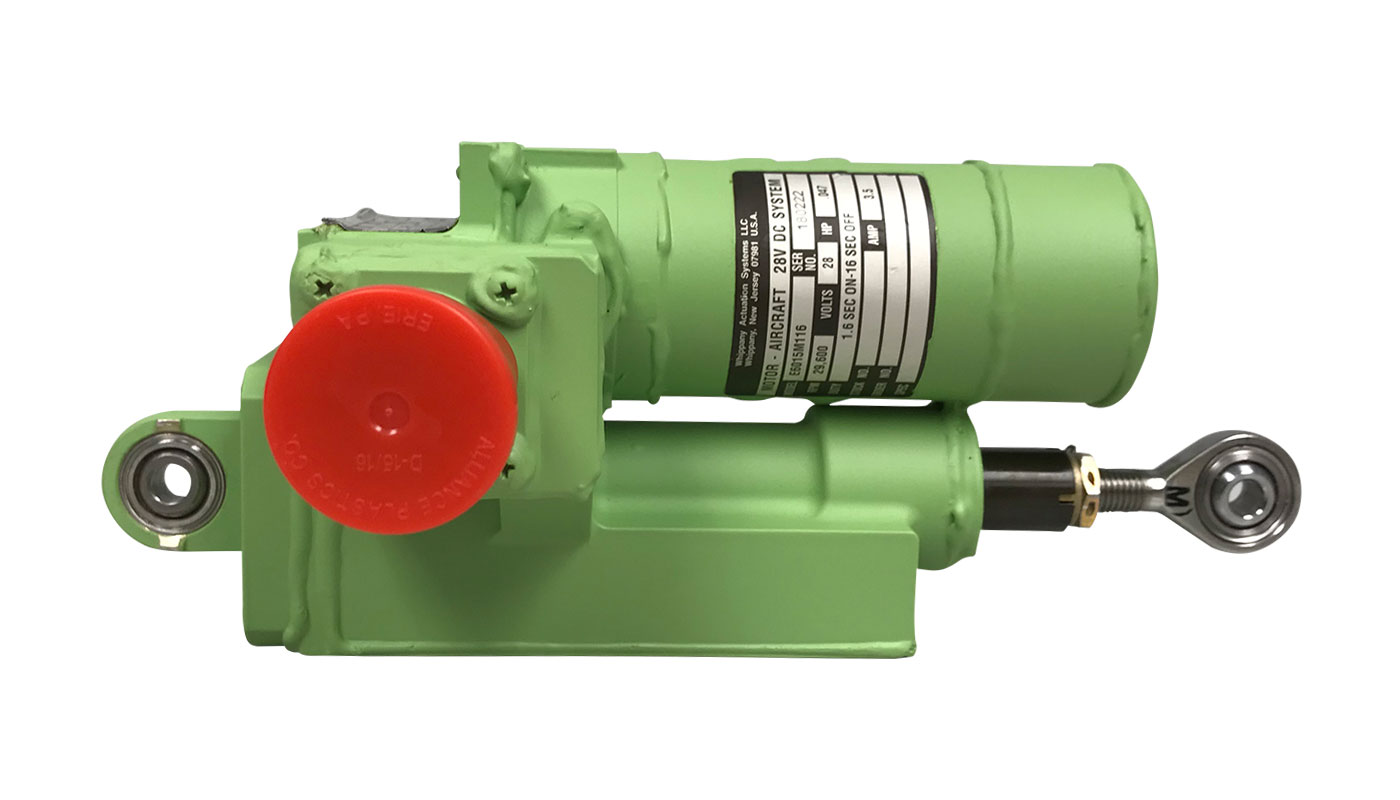

Secondary Flight Control Actuation

Our secondary flight controls support secondary flight surfaces on large and small aircraft alike, each designed to support the platform and meet force, speed, and reliability requirements.

- High Lift

- Trim

- Spoiler

- Authority control/feel

- Brushless DC and AC drive solutions

- Ball screw and acme linear actuators and geared rotary actuators

- Clutches, brakes, dampers, and skewed roller devices

- Custom DC and AC motors

- Transport

- Business jets

- Tankers

- eVTOL

- UAV

- Hypersonic

- Control Surfaces

-

- High Lift

- Trim

- Spoiler

- Authority control/feel

- Features

-

- Brushless DC and AC drive solutions

- Ball screw and acme linear actuators and geared rotary actuators

- Clutches, brakes, dampers, and skewed roller devices

- Custom DC and AC motors

- Applications

-

- Transport

- Business jets

- Tankers

- eVTOL

- UAV

- Hypersonic

Missile/CAS

Our precision missile and target actuation systems provide integrated CAS and component solutions for a variety of missile designs.

- Fins

- Wings

- Integrated CAS and component solutions

- 28 to 270 power interfaces and conditioning

- Multi-loop fin control capability

- Support various autopilot interfaces

- Built-in-test

- Telemetry

- Fin locking and deployment schemes

- High shock and temperature experience

- Non-linear performance modeling and simulation

- Guided rocket

- Loitering missile

- Cruise missile

- Control Surfaces

-

- Fins

- Wings

- Features

-

- Integrated CAS and component solutions

- 28 to 270 power interfaces and conditioning

- Multi-loop fin control capability

- Support various autopilot interfaces

- Built-in-test

- Telemetry

- Fin locking and deployment schemes

- High shock and temperature experience

- Non-linear performance modeling and simulation

- Applications

-

- Guided rocket

- Loitering missile

- Cruise missile

Case Study

NextGen Fighter Aircraft Flight Control

A major aircraft OEM came to Whippany Actuation Systems seeking an electromechanical actuator capable of drawing the electrical power required for next generation fighter aircraft flight controls. Our team was tasked with developing an actuator that meets the high power and bandwidth requirements of hydraulic actuation, a critical technology used by the US Air Force Research Laboratory to support an energy-optimized aircraft power and thermal system.

Whippany developed the highest power actuation system of all participants in the customer’s research program—a 45kW dual redundant controller and electromechanical actuator using proprietary design elements and commercial off-the-shelf hardware. Mission and segment level simulation models supported Whippany’s actuation system, which was timely delivered to meet a rigorous program schedule.